-

About UsProductsCustomized SolutionProjectGalleryNews

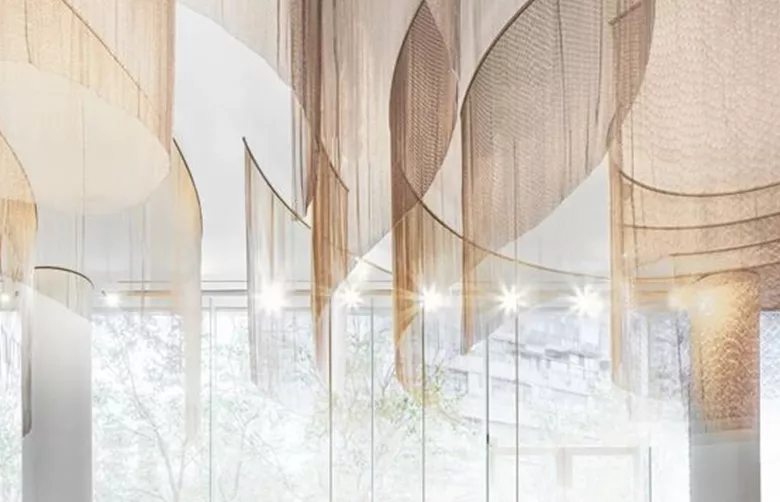

What are some of the challenges of installing woven metal interiors

Release time: July 03, 2023While woven metal interiors offer many benefits, there are also some challenges associated with their installation. Here are some of the challenges of installing woven metal interiors:

Structural Support: Woven metal interiors require appropriate structural support to ensure their stability and longevity. The mesh or fabric panels must be securely anchored to the wall or ceiling, and the framing must be strong enough to support the weight of the metal panels.

Precision: Woven metal interiors require precise installation to ensure that the design is consistent and aesthetically pleasing. The panels must be installed straight and level, and the patterns must be aligned correctly. This requires a high level of precision during installation.

Cutting and Sizing: Woven metal interiors may need to be cut and sized to fit specific areas of the space. This requires specialized tools and expertise to ensure that the metal panels are cut accurately and to the right size.

Electrical and Mechanical Integration: Woven metal interiors may require integration with electrical or mechanical systems, such as lighting or HVAC systems. This requires coordination with other trades and expertise in the integration of these systems.

Safety: The installation of woven metal interiors may require working at height or in confined spaces. This presents safety challenges that must be addressed to ensure the safety of the installation team.

Overall, the installation of woven metal interiors requires specialized skills, equipment, and expertise. Property owners and contractors should work with experienced professionals who have the necessary expertise to ensure that the installation is done safely and accurately. Proper installation is critical to ensuring that woven metal interiors provide the desired aesthetic and functional benefits and remain in good condition for the long term.

Recommended News